BOAT & MOTOR DEALER

JULY 2003

|

TECHNICAL CORNER

|

Many of you may ask, "So what?" Those of you under the age of 40 probably don't know what an OMC 17 was, or what it looked like, so it may be hard to imagine it had much significance. However, as you head into dealer meetings this summer and fall, you'd be wise to keep the OMC 17 in mind. You should be looking for boats that can do what this model did in its day. Its design was to put the customer's comfort and convenience first, and in the process it introduced well-thought-out, revolutionary features that grabbed a lot of attention.

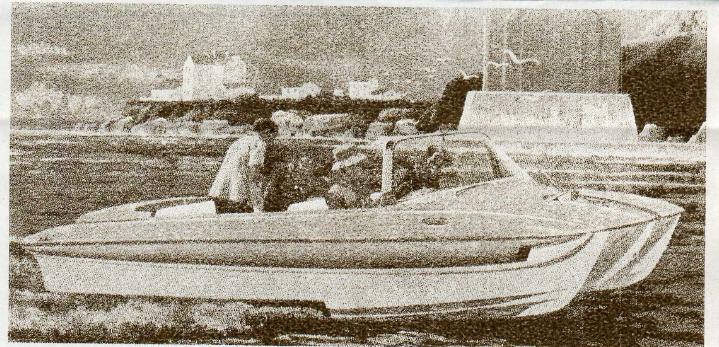

The OMC 17 was a strange looking boat for its day, maybe even for today. It had a hull that rode on three planing surfaces, with two sponsons forward and a shallow vee afterplane. It had a center keel that that began farther aft than the sponsons, ran between them, and sloped gently upwards toward the bow. It was very stable at rest and when underway.

The OMC 17 of 1962-63

The earliest models were underpowered, with a two-cycle V-4 sterndrive that produced only 80 horsepower, and allowed for a top speed of 33-34 mph -- not very fast, even for 1963. In 1964, a 150-horsepower, 4-cycle V-6 Buick sterndrive was offered that pushed the top speed up over 40 mph. With its oil injection and a two gallon oil tank, the two cycle sterndrive had no need for mixing oil and gas. That was more than twenty years before the same feature was offered on the big outboards.

The boat was loaded with features and standard equipment, including: a tempered-glass, tinted wrap-around windshield that was power-operated; five individual bucket seats, with a square life preserved in a recess under a molded seat cushion; full instrumentation; storage bins under the eight-foot-long molded trough on each side, one of which was an insulated beverage cooler; a convertible top that folded under a hatch cover in the stern; side and aft curtains; a combination bilge pump and compartment ventilation blower; a fire extinguisher; four nylon dock lines with a spliced in loop at one end; and even a custom-designed folding boarding ladder.

The lightweight seats were quickly removable for use on shore or to clear more floor space for cargo. The stern drive had 75-degree tilt, 90-degree steering with a no-feedback system and electric gearshift controls. All this came with a list price of $3,495. A custom designed all-roller trailer, manufactured at the same plant as the boat, was also available. The trailer had electric brakes and a lever-operated tilt bed.

Between the flat interior floor and the bottom were two fiberglass hat-section stringers with aluminum plates molded in for the engine mounts, of which there were only two on the floor for th two-cycle V-4 sterndrive. The upper mounts were bolted to an aluminum beam running across the inside of the transom. The stringers were filled with high-density urethane form, as were all the empty spaces between the floor and the bottom. Plenty of room was left under the engine, making it easy to keep clean. The bilge-pump/blower-unit was mounted in a sump molded into the floor panel. If the water level ever got high enough to submerge the entire unit, both the pump and the blower on top of the sealed electric-motor housing would pump water out of the boat.

The high-density foam in the bottom was mainly for support, but it also made the boat unsinkable. One of the side benefits of the OMC 17's unique bottom design was that it placed a large amount of foam out in the sponsons on either side forward. And the deepest part of the foam near the stern between the stringers, giving the boat three-point buoyancy. The result was that the OMC 17 floated level and upright when swamped. In fact, every boat that OMC designed in built in the 8 years they were in the boatbuilding business had this capability.

You could also leave the drain plug out of your OMC 17 and stay on board, because there was no place for water to go under the floor. In fact all five 170-pound people the boat had seats for could stay in the boat with the plug out, and it still floated with the hull-to-deck molding out of the water. This was a safety feature worth talking about. Virtually all fiberglass boats built in the early 1960's sank when swamped, or loaded with only their bows out of the water. Changing the Industry

The OMC 17's remarkable flotation characteristics came to the attention of the American Boat and Yacht Council, and what was to become it's Hull Performance Project Technical Committee. In the early 1970's more than 1,700 people were dying each year in boat accidents -- mostly in boats less than 20 feet long. Clearly, the OMC 17 offered some promising solutions to this trend. One result of the committee's investigation was the enactment of the "ABYC" Standard H-8 for outboard boats under 20 feet in length," which required that all such boats float level and upright when swamped with their rated passenger load centrally located on board.

This meant that passengers in a flooded boat would only get wet up to their waists if the didn't panic and they were not out in big waves. Such boats would also be stable when inverted, providing a large, unsinkable, and highly visible object to hang on to. Major boat manufacturers began to follow the standard voluntarily.

Also in the early 1970's the Boating Safety Act was enacted, empowering the Coast Guard to establish regulations for recreational boats aimed at reducing the rate of boating fatalities and injuries. The causes of these accidents were analyzed, and it became apparent that the greatest reduction could be made by doing two things: increasing the availability and use of personal flotation devices, and making it possible for the passengers to stay with the boat, whatever condition it may be in. The level-flotation requirements of the ABYC standard were among the first federal safety regulations, along with a requirement that a PFD be carried on board for every passenger.

These requirements addressed the causes of more than two-thirds of the boating fatalities, and were further targeted for outboard-powered boats less than 20 feet in length -- the boats most frequently involved in fatal accidents. The rules were somewhat relaxed, though, for inboard boats, due to the difficulty of keeping a boat's stern afloat with an 800-pound engine located there. Inboard boats were required to only have "basic floatation," meaning that the vessel would have to stay afloat, but not necessarily as a stable and level platform. At the same time, federal regulations also enacted standards for the fuel and electrical systems, ignition protection of electrical components in gasoline engine and fuel-tank spaces, positive compartment ventilation and so on.

Thirty years after the regulatory process was initiated, annual boating fatalities in the United States have declined from more than 1,700 to about 700.

While it may be a stretch to give OMC all the credit for establishing these manufacturing standards, it's clear that they led the way. Someone had to show that it could be done. OMC produced more than 6,000 boats a year -- mostly inboards -- in the late 1960's and each one of them had level and upright flotation. The OMC 17 was the first of that line, and as such, it deserves our recognition.

Ralph Lambrecht is an engineer with more than 50 years experience, in the marine industry and marine safety standards development.